Hydraulic fittings manufactured by Hydromatik confirms to the performance requirement specified in ISO 8434, SAE J514, SAE J1453. Below are few of our testing facilities.

Allows us to test our fittings as per ISO 19879, including Repeated assembly test, Leakage Test, Proof Test, Burst Test, Cyclic endurance test (Impulse Test), Vacuum Test, Overtightening Test and Vibration test.

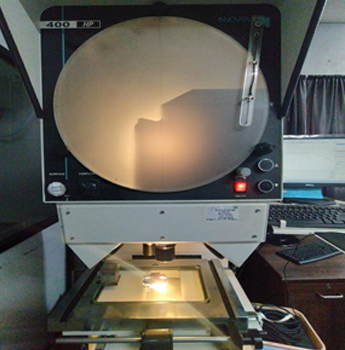

All external critical dimensions such as JIC 37 Deg chamfer, 60 Deg Chamfer, Radius, Undercut Lengths will be measured on Vertical Profile Projector

Determining Internal critical profiles such as angles, radii, distances and co-ordination as well as computer controlled nominal-actual comparison with measured or CAD-based profile data. Providing accurate and repeatable results without the need to destroy parts.

We have testing capabilities to ISO 4405 and to specific customer requirements. We also use a microscope with digital cameras and software that allows us to measure particle sizes.

Salt Spray Test is performed as per conditions specified in standard ASTM B 117 : 2018

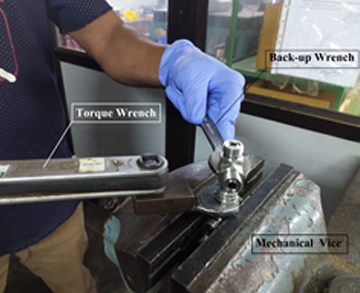

Apply Over-Torque mentioned in respective connector standard on Nut by maintaining connector orientation with backup wrench as shown

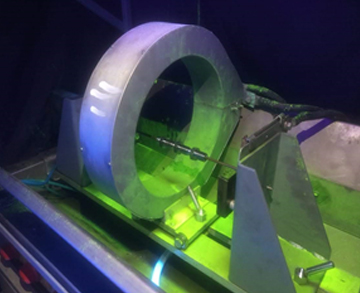

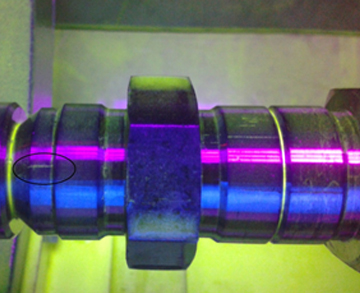

Magnaflux inspection is a method to find surface defects like fatigue cracks in ferrous materials through wet method.