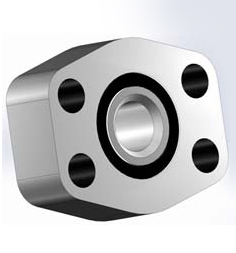

6000 PSI Series (Code 62) Flange recommend screw torque

Dush

size |

Flange

size |

Inch screws

(J518) |

Torure

(Nm1) |

Metric screws

(ISO 6162) |

Torque

(Nm1) |

| 13 |

1/2" |

5/16-18 |

24 |

M8 |

24 |

| 19 |

3/4" |

3/8-16. |

43 |

M10 |

50 |

| 25 |

1" |

3/8-16. |

43 |

M10 |

50 |

| 32 |

1.1/4" |

7/16-14. |

70 |

M10 |

50 |

| 38 |

1.1/2" |

1/2-13. |

105 |

M12 |

92 |

| 51 |

2" |

1/2-13. |

105 |

M12 |

92 |