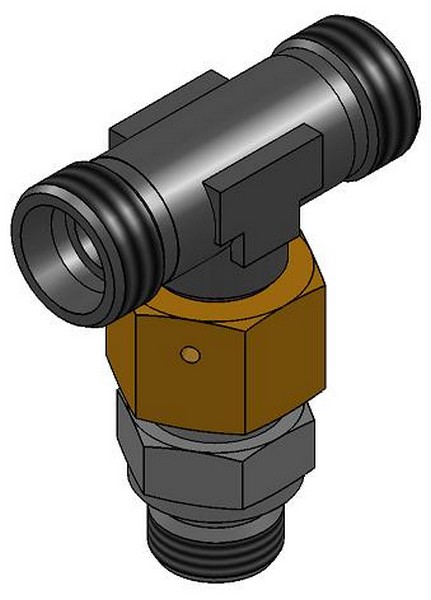

| R - Part No. | M - Part No. | Series | Tube OD | BSP Thread G | Metric Thread G | l1 | l2 | S1 | S2 | S3 |

|---|---|---|---|---|---|---|---|---|---|---|

| ET 06-LR-ED | ET 06-LM-ED | Light-250 Bar | 6 | 1/8 | M10 X 1 | 12 | 34.5 | 14 | 14 | 12 |

| ET 08-LR-ED | ET 08-LM-ED | Light-250 Bar | 8 | 1/4 | M12 X 1.5 | 14 | 37.5 | 19 | 17 | 12 |

| ET 10-LR-ED | ET 10-LM-ED | Light-250 Bar | 10 | 1/4 | M14 X 1.5 | 15 | 40 | 19 | 19 | 14 |

| ET 12-LR-ED | ET 12-LM-ED | Light-250 Bar | 12 | 3/8 | M16 X 1.5 | 17 | 42 | 22 | 22 | 17 |

| ET 15-LR-ED | ET 15-LM-ED | Light-250 Bar | 15 | 1/2 | M18 X 1.5 | 21 | 46.5 | 27 | 27 | 19 |

| ET 18-LR-ED | ET 18-LM-ED | Light-160 Bar | 18 | 1/2 | M22 X 1.5 | 23.5 | 50 | 27 | 32 | 24 |

| ET 22-LR-ED | ET 22-LM-ED | Light-160 Bar | 22 | 3/4 | M26 X 1.5 | 27.5 | 55 | 32 | 36 | 27 |

| ET 28-LR-ED | ET 28-LM-ED | Light-100 Bar | 28 | 1 | M33 X 2.0 | 30.5 | 59 | 41 | 41 | 36 |

| ET 35-LR-ED | ET 35-LM-ED | Light-100 Bar | 35 | 11/4 | M42 X 2.0 | 34.5 | 68.5 | 50 | 50 | 41 |

| ET 42-LR-ED | ET 42-LM-ED | Light-100 Bar | 42 | 11/2 | M48 X 2.0 | 40 | 75 | 55 | 60 | 50 |

| ET 06-SR-ED | ET 06-SM-ED | Heavy-630 Bar | 6 | 1/4 | M12 X 1.5 | 16 | 40 | 19 | 17 | 12 |

| ET 08-SR-ED | ET 08-SM-ED | Heavy-630 Bar | 8 | 1/4 | M14 X 1.5 | 17 | 42.5 | 19 | 19 | 14 |

| ET 10-SR-ED | ET 10-SM-ED | Heavy-630 Bar | 10 | 3/8 | M16 X 1.5 | 17.5 | 45 | 22 | 22 | 17 |

| ET 12-SR-ED | ET 12-SM-ED | Heavy-630 Bar | 12 | 3/8 | M18 X 1.5 | 21.5 | 48 | 22 | 24 | 17 |

| ET 14-SR-ED | ET 14-SM-ED | Heavy-630 Bar | 14 | 1/2 | M20 X 1.5 | 22 | 54 | 27 | 27 | 19 |

| ET 16-SR-ED | ET 16-SM-ED | Heavy-400 Bar | 16 | 1/2 | M22 X 1.5 | 24.5 | 55 | 27 | 30 | 24 |

| ET 20-SR-ED | ET 20-SM-ED | Heavy-400 Bar | 20 | 3/4 | M27 X 2.0 | 26.5 | 65 | 32 | 36 | 27 |

| ET 25-SR-ED | ET 25-SM-ED | Heavy-400 Bar | 25 | 1 | M33 X 2.0 | 30 | 73 | 41 | 46 | 36 |

| ET 30-SR-ED | ET 30-SM-ED | Heavy-250 Bar | 30 | 11/4 | M42 X 2.0 | 35.5 | 78.5 | 50 | 50 | 41 |

| ET 38-SR-ED | ET 38-SM-ED | Heavy-250 Bar | 38 | 11/2 | M48 X 2.0 | 41 | 89 | 55 | 60 | 50 |

| Dimensions given approx.,fig. with tightened nut Temp range without pressure reductions for 'O' Ring sealing of NBR (buna N- Std) -35° to +100° C, for FPM (Viton - On request) -25° to +120° C. |